Modern Material Handling Feature: Automation where it counts at ÐÇ¿Õ´«Ã½

By deploying a drone-based inventory monitoring solution at its Hillsborough, N.J., facility, ÐÇ¿Õ´«Ã½ ÐÇ¿Õ´«Ã½Centers, a growing 3PL, has taken license plate accuracy to the next level, helping with order picking and eliminating time spent on manual cycle counts.

By at

Extremely high accuracy over sitting in storage is a nice thing to have in a DC, but traditionally it has come at a cost: hours of labor spent hand-scanning bar coded license plates or “LPs” on pallets or cases and then reconciling any discrepancies.

Of course, the cost of not expending labor on LP accuracy is downstream delays in filling orders due to misplaced inventory. Given the choice between unhappy customers or expending some labor on LP counts and inventory adjustments, many operations have chosen some form of LP counting and inventory monitoring.

This dedication to inventory accuracy has long been a pillar of operational excellence for ÐÇ¿Õ´«Ã½ ÐÇ¿Õ´«Ã½Centers, a company, explains, ÐÇ¿Õ´«Ã½’s vice president of business process optimization.

“LP accuracy is one of our key internal drivers for success at ÐÇ¿Õ´«Ã½. The more accurate your inventory is, the more productive you can be—because you don’t have unexpected shortages—so you can just pick orders instead of searching for inventory or having to replenish,” says Rapoza. “Our senior leadership team, Tim ÐÇ¿Õ´«Ã½ and Art ÐÇ¿Õ´«Ã½, also view high LP accuracy as a driver for employee satisfaction because when it comes time to pick, our associates can execute their work without delay, which contributes to a high level of job satisfaction. As a result, we take LP accuracy very seriously, because it’s good for our customers, and it’s also good for our employees.”

The last couple of years have seen ÐÇ¿Õ´«Ã½ ÐÇ¿Õ´«Ã½Centers further improve on LP accuracy while removing the cost involved in manual data collection by deploying a warehouse drone solution ( to automate the reading and monitoring of LP labels in storage positions. The system’s software, which uses provides a dashboard view that compares what the drone missions find against data.

ÐÇ¿Õ´«Ã½ doesn’t use the drones at all of its warehouses, but it does use them at six sites to automate the counting of LP bar codes on pallets or to count unique cases with LP bar codes.

A single operator managing a drone mission can capture LPs more quickly and accurately than a team of inventory specialists can with manual scanning. The cost comparison is not even close, Rapoza adds. Manual LP cycle counting costs roughly $1.50 per scan; and the drone system costs around 10 to 20 cents per scan—a fraction of the cost.

The drones have been effective at reading the labels and generating reports that pinpoint any inventory variances with ÐÇ¿Õ´«Ã½’s WMS. At sites that use the drones, LP accuracy exceeds 99%, and at one facility in Hillsborough, N.J., where the drones are used to capture LPs on unique cases, the accuracy level has reached 99.9%. The drones are used frequently to keep LP accuracy at a near-perfect level.

“The ease of being able to capture a high volume of LP information with a single drone, compared to using a team of people, means that we can perform LP cycle counts more frequently now, so the inventory variances surface much faster,” says Rapoza. “When we first deployed the drones, we saw a pretty significant spike in inventory variances that we were then able to correct in a much shorter time-frame than if we were just deploying people to count LPs. That helps us keep inventory accuracy optimally high for the sites and areas we’ve deployed them in.”

Targeted use cases

Since 1941, ÐÇ¿Õ´«Ã½ has provided 3PL services, including direct-to-consumer (DTC) fulfillment, omni-channel distribution, as well as transportation management and retail compliance for clients.

Customers represent industries including apparel and footwear, health and beauty, consumer packaged goods, consumer electronics, food, candy, grocery and automotive. The company currently has 23 DCs nationwide comprising roughly 7 million square feet, including sites in Greater Boston, New Jersey, New York, Baltimore, Memphis, Dallas and California.

With a motto of, “Big enough to do the job and still small enough to deeply care about your business,” ÐÇ¿Õ´«Ã½ adapts its services around the fulfillment needs of its clients. For most of its clients, the WMS used to manage and fulfill orders is based on a system called Synapse (, formerly Zethcon).

The use of Gather AI drones across ÐÇ¿Õ´«Ã½’s network is largely focused on reading LPs on pallets, though at its fulfillment center in Hillsborough, N.J., the drones are used to scan LP labels on unique cases of shoes for ÐÇ¿Õ´«Ã½’s client Stadium Goods, a sneaker and apparel marketplace. These aren’t the average sneakers one would find at any retail store, but rather, collector and special edition shoes that in some instances might fetch several thousand dollars per pair. Most end-customers are typically buying one pair of unique shoes.

As a result, one shoebox with one pair of shoes typically equates to one case for the vast majority of goods in storage at Hillsborough. An inventory authentication team from Stadium Goods works on site to authenticate each pair of shoes coming in before it is processed and stored by ÐÇ¿Õ´«Ã½ associates.

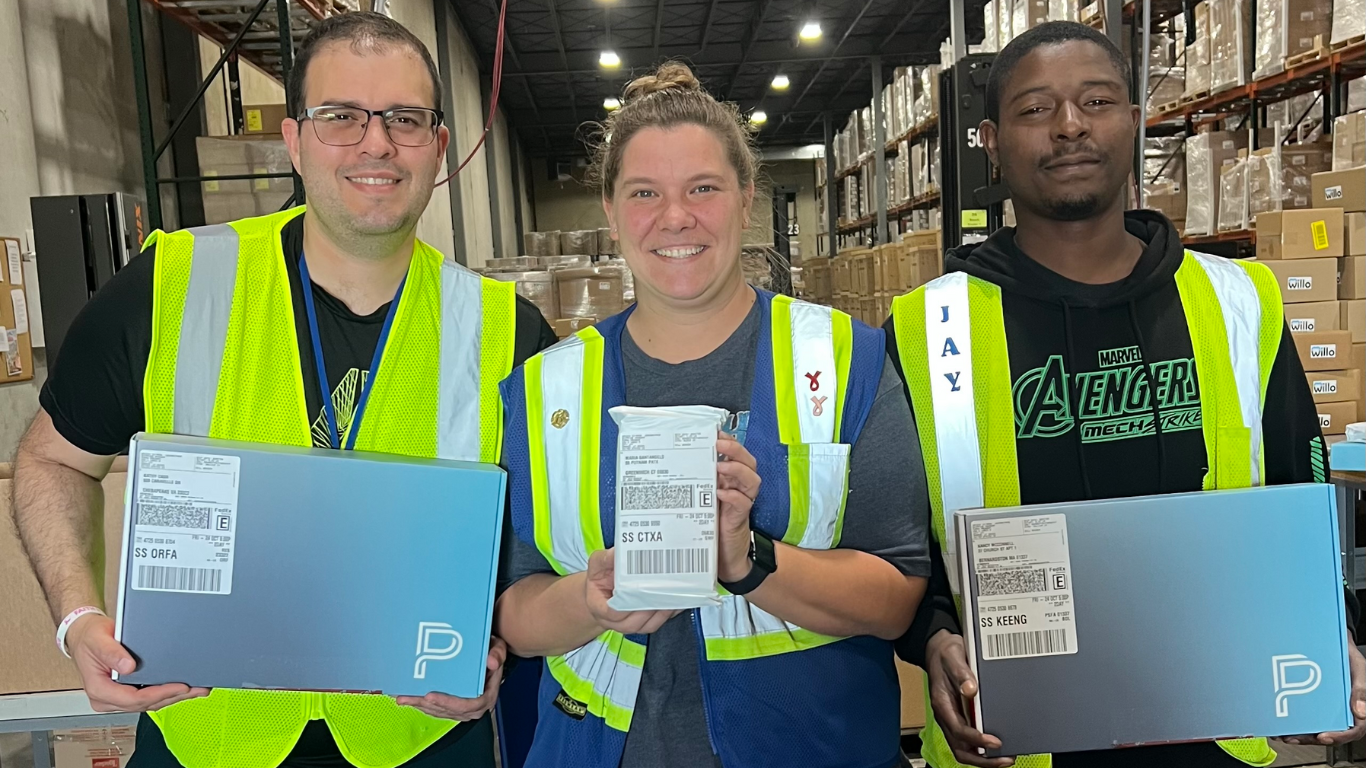

Each case is polybagged at the DC after being authenticated, with a unique LP bar code placed on the bag prior to being placed in very narrow aisle (VNA) storage with selective racking. The site uses a modified auto bagging system with a print-and-apply function (Sealed Air) to automate the process of placing each shoebox into a Stadium Goods branded polybag and applying the LP bar code to it.

While a small percentage of these unique cases hold a few pairs of shoes or other apparel items, the vast majority of the cases/bags hold one pair of shoes. Usually, the Hillsborough location has close to a half-million pairs of shoes or other unique cases for Stadium Goods stored on the 34 aisles of VNA racking. When it comes time to fill orders, the picking is done from the VNA storage by associates on orderpickers.

The Stadium Goods inventory is ideal for drone inventory monitoring, says Rapoza, since each case is a unique, high-value item that needs to be in the location the WMS indicates it will be in, since there is no handy supply of the same SKU in reserve. High LP accuracy is important for all of ÐÇ¿Õ´«Ã½’s clients and processes, Rapoza explains, but for Stadium Goods, it’s a must.

“We run the drones in a handful of facilities for different storage mediums, but for Stadium Goods, we had a unique value proposition for the drones, because the end customer is buying a specific pair of shoes, so the LP accuracy has to be near perfect,” Rapoza says. “If you think about it, we need to pick a specific pair of shoes, and if those shoes aren’t in the exact location where our WMS system says they should be, now you have to go find that case in a sea of a half-million pairs of shoes.”

Before deploying the drone solution, ÐÇ¿Õ´«Ã½ maintained a high level of LP accuracy for Stadium Goods by manual cycle counting by ÐÇ¿Õ´«Ã½’s team of inventory control specialists. Now, however, the drones automate the data capture piece, with one inventory control specialist able to manage each drone flight, rather than needing a whole team of people to go out to periodically scan all the LPs in a section of the VNA storage.

Importantly, adds Rapoza, the drones aren’t only a time saver for the inventory team.

“Yes, the drone solution eliminates the need to have our inventory control associates spend time manually scanning LP labels, but the benefit goes beyond labor savings for that one task,” Rapoza says. “The system helps with customer satisfaction and same-day service levels by supporting the need to get the product out the door accurately and on time. The higher we can make our LP accuracy, the more we are going to improve all our downstream processes.”

Running the drones

“The drone missions are run frequently to capture LP images and data from a predefined section of VNA storage at Hillsborough,” explains , operations manager for the site.

There are 34 VNA aisles in total. Each aisle has 26 bays, and each bay has 10 levels of case storage. Typically, one drone mission will scan all the LPs within 10 full bays of one aisle.

Drone flights are usually run during break times or toward the end of a shift when the order picking activity in a section of aisles has ceased or slowed so the aisle can be blocked off with cones and the drone flight can run without worry of interrupting order picking.

One inventory quality control staffer manages each drone mission. A single drone flies autonomously within the aisle once the mission is set up—the associate isn’t working a joystick to fly the unit—but it does require some human oversight to set up and close out a mission. The Hillsborough site keeps two drones on hand, to have one as backup.

Once each drone flight is complete, the Gather AI dashboard highlights any variances against what the mission found, and what ÐÇ¿Õ´«Ã½’s WMS says should be in the locations just scanned. In the event there is a variance, it’s investigated and corrected.

Right-sized packaging efficiency

“The CMC system helps us by building boxes around each order to help us reduce the cost of shipping, by having that right-sized carton, while also reducing the manual labor that was previously needed for packing out those orders,” - Rapoza

Another way ÐÇ¿Õ´«Ã½ ÐÇ¿Õ´«Ã½Centers is bringing targeted efficiencies to its order fulfillment for Stadium Goods at the Hillsborough, N.J., facility is through packaging automation. Specifically, ÐÇ¿Õ´«Ã½ deployed an automatic carton packaging system (CMC Packaging Automation) that forms perfectly sized shipping cartons for shoes being fulfilled on behalf of Stadium Goods.

The CMC CartonWrap machine rapidly creates custom shipping cartons from fanfold-fed corrugated cardboard, right-sized to fit around the shoeboxes being shipped to fill single-line orders. The system also automatically applies the shipping label.

Before using the system, packaging single-line orders for Stadium Goods was done using manual pack out stations, with up to 27 stations in use during peak times. Now, except for times of peak order volume, the automation handles the pack out tasks, with 12 pack out stations in reserve for peak times or multi-line orders.

“The CMC system helps us by building boxes around each order to help us reduce the cost of shipping, by having that right-sized carton, while also reducing the manual labor that was previously needed for packing out those orders,” says Rapoza. “There is no direct tie between the drone system and the CMC solution, though ultimately, they are both components of how we are driving down costs while hitting service level agreements through the use of some of these technologies.”

To help reduce the information technology time and effort involved in integrating the right-sized packaging automation system with its WMS, ÐÇ¿Õ´«Ã½ used an integration software platform (SVT Robotics). ÐÇ¿Õ´«Ã½ also plans to use the platform to simplify the development of full bi-directional integration between its drone inventory monitoring system and its WMS.

The end result is near perfect LP accuracy for the unique cases held in the VNA storage for Stadium Goods. “The LP accuracy is 99.9% or better, so in practice, we know we have every pair of shoes in the building in the right location, so when it’s time to pick, those shoes are right where they are supposed to be,” says Glanzer. “That level of LP accuracy positively impacts everything we need to do downstream, for the pickers, for the packers, and for getting each shipment on the truck at the right time, to meet the end customer’s delivery expectation.”

Glanzer says the drones have proved valuable for tracking LPs on pallets at Hillsborough for other clients, though the drone monitoring holds especially high value for Stadium Goods. “When it is time to pick, the cases are there literally 100% of the time,” he says. “What makes it so effective is that this case inventory is all unique, with its own LP bar code, readable by a drone in the storage medium.”

Sometimes a drone might return a blurred image, but these can usually be zoomed in on enough to read the LP bar code and determine if the case is in the correct location, says Glanzer.

Another lesson ÐÇ¿Õ´«Ã½ has learned about the use of drones is that when they are reading LPs on pallets, there should not be excessive pallet overhang, to minimize the risk of a drone striking a pallet. Consistent placement of LP labels helps make the drone system more effective.

ÐÇ¿Õ´«Ã½ and Gather AI will be working on integration between the drone system’s software and the WMS so variances and count details can flow right into the WMS to simplify the updating of data and creation of any corrective moves. Integration software initially brought on by ÐÇ¿Õ´«Ã½ to speed up the integration of a right-sized, packaging automation solution with its WMS (see box, page 24), is expected to help with this integration between the Gather AI system and the WMS.

Targeted efficiency

ÐÇ¿Õ´«Ã½ is selective in how it leverages the drones, adds Rapoza. For example, it isn’t used in typical forward picking areas where a drone would lack a clear line of sight to bar codes, and for which associates already have system-directed manual scan verification steps in WMS to ensure accuracy. But for very efficiently counting LPs on pallets or cases, especially for fast-moving goods or unique cases, the drones are a labor efficient way to take LP accuracy to the next level.

“Our LP cycle count program with the drones is really focused on what moves, instead of counting product that sits there, like a D-level SKU,” says Rapoza. “For those goods, the drone technology allows us to capture LP data much more efficiently, with much fewer labor hours, and with greater accuracy, than what we could do with a manual counting process. It helps achieve higher quality, at a lower cost.”

Recent Blog Posts